If we don't have it,

let's create it.

LIXIL’s passion is to create products that surprise and delight our customers.

We have continuously challenged the status quo and

delivered new technologies before our competitors,

always in pursuit of what customers might need or want.

This year marks the half century of the first made-in-Japan

shower toilet we launched in 1967. Introduced here are the various technologies

that have provided new benefits to our customers since then.

Technologies developed for

the first made-in-Japan shower toilet

– a legacy we've inherited to this day

1967 Sanitarina 61

1967 – The launch of Sanitarina 61, the first made-in-Japan shower toilet.

During the era of rapid economic growth in Japan in the 1960s, more and more households started to have flush toilets, as the country modernized its above- and below-ground drainage system. Furthermore, the Japanese had begun to adopt western-style toilets, triggered by their installation in the Athletes' Village of the Tokyo Olympic Games. It was against such societal backdrop that INAX, one of the founding companies of LIXIL, launched Sanitarina 61, the first domestically-produced shower toilet in 1967. At the time, the only shower toilets sold in Japan were those imported from overseas as medical devices. The launch of Sanitarina 61 marked the beginning of the gradual trend for shower toilets to be used commonly in ordinary Japanese homes.

A project delivered by only several members.

The project members at the time.Today, shower toilets are identified as a distinct Japanese culture. The development of the first product, however, was actually started with only several project members. The imported shower toilet was the only available product at the time. The team found that the warm water and air ejected from the imported product just did not fit well to Japanese physique, so the first challenge was to find the right position of the nozzle, to satisfy Japanese users. The team checked everywhere including asking gynecologists and proctologists for data on Japanese bottoms, but such information was nowhere to be found.

Figuring out the best nozzle position for Japanese users.

Having struggled in vain without any useful data, the team decided to start by measuring the positions of tailbones and anuses of employees. However, figuring out the "standard" position was itself a challenge, as people were not yet used to western-style toilets and therefore how they sat on the toilet seats differed. After measuring many times over, the position of the nozzle was finally determined. Multiple-layer controls were devised in the hot water temperature setting function, to completely eliminate the risk of users getting burned due to any system malfunction. In 1984, the product was given the name "shower toilet", representing its comfortable warm-water washing and a refreshing blow-drying features.

80 degrees' angle. The ultimate nozzle position.

The easy-to-wash nozzle angle.

The key aspect of shower toilets is the comfortable washing experience, the determining factor of which lies in the angle of the nozzle. A more thorough wash could be achieved by extending the nozzle to directly below the user's bottom and spraying the water vertically, compared to doing so at a shallow angle. However, a vertical wash also meant a high chance of splash-back onto the nozzle. Therefore, in developing Sanitarina 61, the team studied the nozzle angle at great length and finally determined that 80 degrees was the ultimate angle to achieve the utmost wash while keeping the nozzle hygienic. This concept of the nozzle angle still prevails in LIXIL's shower toilets, today.

1976

1976 – Launch of Sanitarina F1, INAX's first shower toilet seat.

In 1976, INAX launched Sanitarina F1, which allowed ordinary toilets to become shower toilets by just changing the toilet seats. Shower toilet seats are highly popular today, as users can obtain the most up-to-date functions by changing just their toilet seats. The know-how gained to produce Sanitarina 61 was used to develop the shower toilet seat, and this launch contributed to the expansion of shower toilet adoption in ordinary households.

Sanitarina F1

Eliminating the stress

associated with toilet cleaning.

1996

Development of antibacterial toilet seats.

Technologies that eliminate the stress of toilet cleaning may be the innovations that are most easily appreciated by our users. KILAMIC, Japan's first antibacterial technology launched by INAX in 1996, is a prime example of such technologies. This proprietary technology, which involved the use of highly antimicrobial silver ions, was very well received, as it prevented bacterial growth and pile up of stains. The technology was certified as an international standard in 2007 by the International Standard Organization (ISO), and LIXIL's toilets are today exported globally, all with the ISO mark attached.

2001

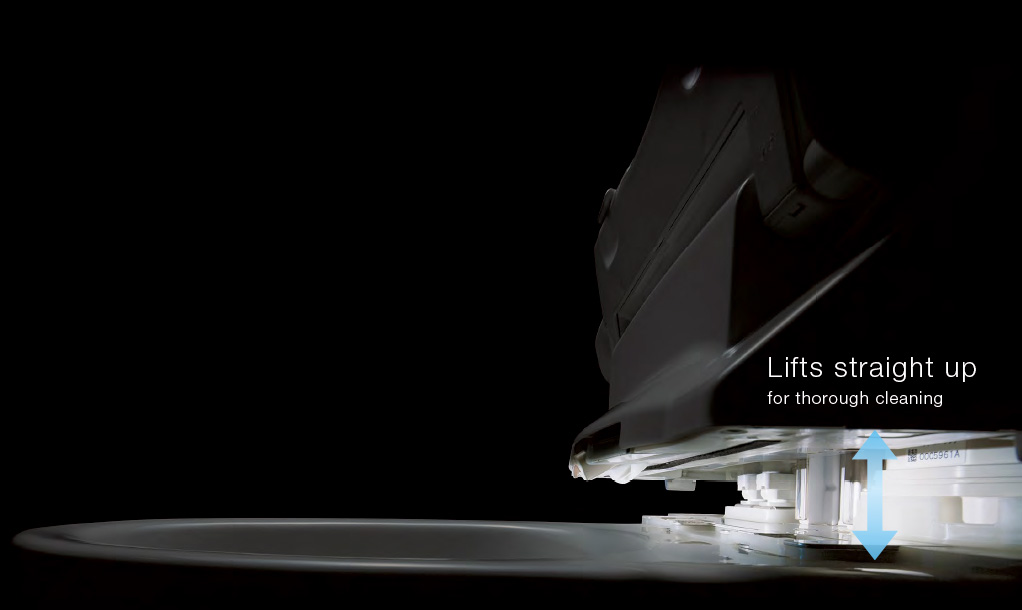

Launch of the industry's first Easy Clean Lift.

LIXIL first developed the shower toilet seat that can be detached entirely by sliding the toilet seat. Expanding on this technology, in 2001, we added the Easy Clean Lift feature to our integrated shower toilet products. The toilet seat lifts straight up, making it easy to wipe off any stain in the gap between the seat and the toilet bowl and thereby eliminate the root cause of toilet odor. Ever since its first launch, this function has continued to win the hearts of our customers. The uniqueness of LIXIL's Easy Clean Lift feature lies in the fact that the entire toilet seat rises vertically. As a result, the gap is wide enough to be thoroughly cleaned even with male hands, thereby ensuring LIXIL 's commitment to cleanliness.

Easy Clean Lift

2009

The Seamless Seat.

The Seamless Seat, which eliminated the seam into which stains penetrated, was also well-received by our customers. Cleaning the toilet seat was a cause of stress, as the stains in the toilet seat seam needed to be removed using tools such as a thin rod. The Seamless Seat appears as though it is molded into one piece, but it is actually made by welding and polishing two resin pieces.

Conventional toilet seat

The stains in the seam is very difficult to remove.

The Seamless Seat

No seam into which stains can penetrate.

Attention to details and the spirit of hospitality

have continued to enhance comfort.

1988

LIXIL's unique feature, Lady Nozzle for women.

Some features in bathrooms are not critically necessary but make a world of difference in the added comforts they provide to users. Such features are developed by thinking from the users' perspectives and identifying and catering to their specific needs. One example of such features is the Lady Nozzle. LIXIL's shower toilets feature two nozzles, one for the rear wash and one dedicated to the bidet function for ladies, catering to the concerns of many women about washing their sensitive intimate areas with the same nozzle as the one for the rear wash. The Lady Nozzle is designed to offer a softer shower wash, made possible by spraying water mixed with air from multiple holes. The tip of the nozzle can be detached and replaced, allowing the nozzle to remain hygienic for a long time.

Lady Nozzle

1992

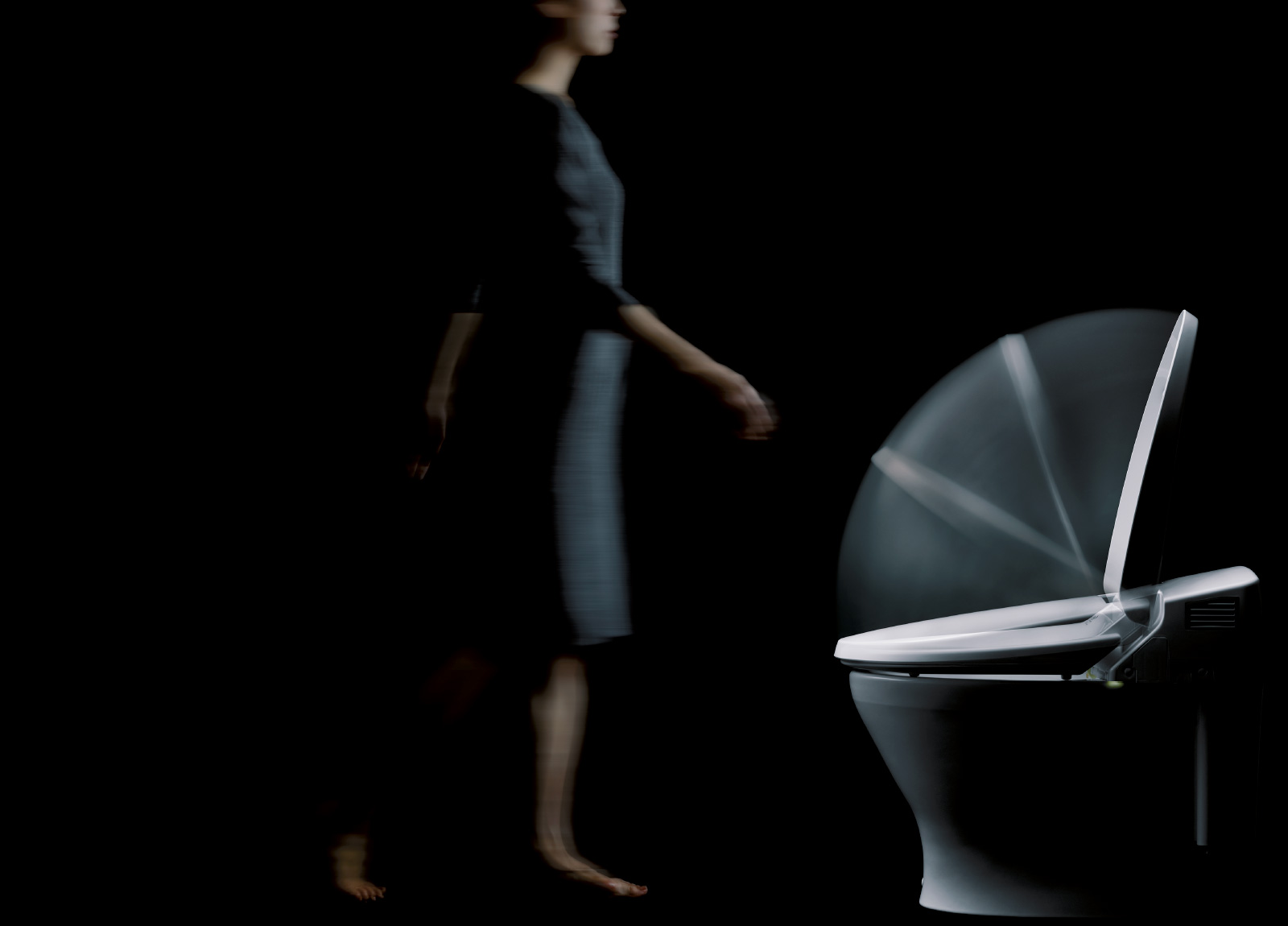

The industry's first AutoSeat, the hygienic alternative to using hands.

LIXIL was also the first in the industry to develop and commercialize AutoSeat, the feature which allows the lid and/or seat to rise automatically when you approach and lower when you leave the toilet. Responding to the rising interest in hygiene in the society, this feature made it possible to use the toilet without touching the toilet seat. In recent years, with the increasingly greying society, this feature is also in line with the universal design principles, as it helps to reduce the strain on the back.

1995

The industry's first AutoFlush, ensuring that no mess is left behind.

LIXIL was also the first in the industry to develop and launch the automatic flushing feature, AutoFlush eliminating the need to use the handle. The toilet automatically determines how much water is necessary depending on how long the user has been sitting on the seat and automatically flushes when the user stands up. LIXIL has been at the forefront in developing such industry leading technologies. Such innovations confirm our commitment to continuously seek for new and additional comfort, looking at the toilet experience from our customers' perspectives.

AutoFlush

Changing the bathroom into a

comfortable living space.

2001

satis - the world's smallest high-function shower toilet.

The world's smallest tankless toilet, satis, was launched following a three year development period. The concept was to produce a toilet that is smallest in the world and provides maximum satisfaction and thereby develop the bathroom into a living room. The final product measured only 650mm from the wall to the tip of the toilet bowl. In pursuing this challenge, we weren't just focused on achieving the reduction in numbers. By eliminating the tank, our main objective was to reduce the size of the toilet system itself, thereby making the restroom more spacious and comfortable. Reviewing and restructuring the overall layout including the control circuit of satis, we succeeded in reducing the size of the electronic system of the toilet, while retaining existing features as well as adding new ones. Within a 1.3m2 restroom, we managed to expand the space in front of the toilet seat by 35%.

satis (2001): Stylish straight-line design

2016

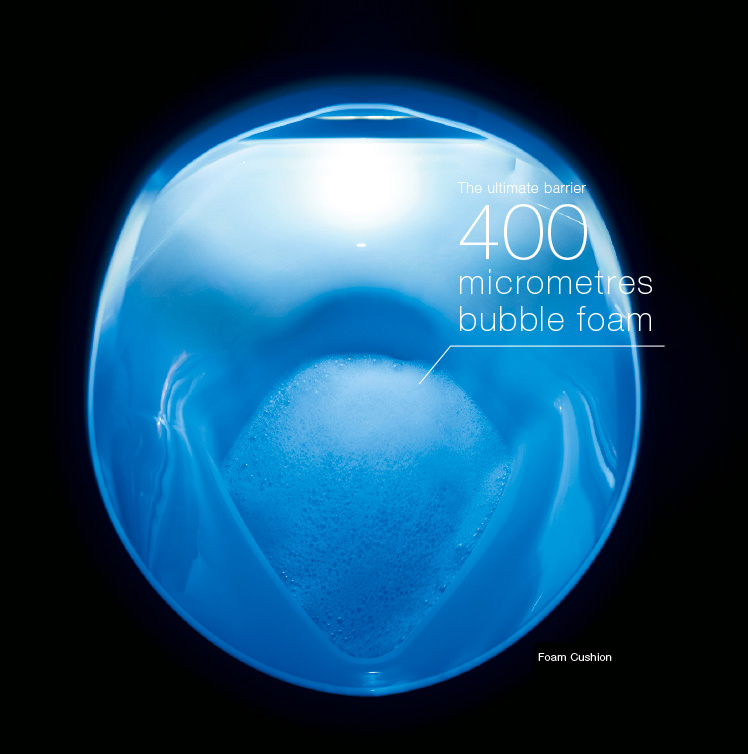

Foam Cushion – newly developed

micro foam to reduce urine splash.

LIXIL's unique technology automatically creates a 5-15mm thick fine foam with a bubble diameter of 400μm (micrometres) or less in the toilet bowl. We found the optimum size of the foam to limit urine splash, after repeatedly testing and evaluating the time it should take for the foam to be prepared after the toilet seat rises, as well as the right ratio of water, detergent, and air, and the order in which they are mixed.

2016

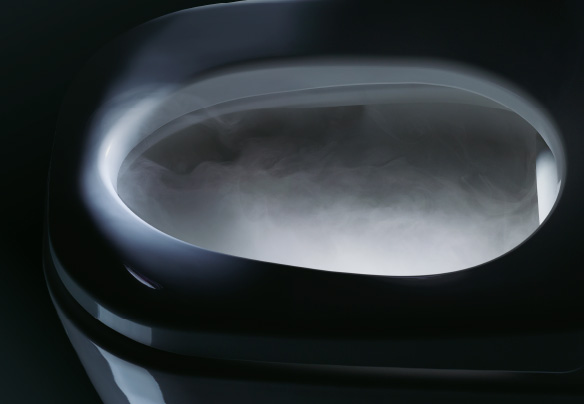

Air Shield Deodorization – reducing odors by 43%*

compared to conventional toilets.

The history of LIXIL's pursuit for deodorization dates back to 1984, when it launched its first toilet equipped with deodorization features. In 1989, we added the exhaust deodorization technology to Shower Toilet DII, which was designed to capture the odoriferous air from the toilet bowl and flow it into the sewer pipe. From 1992, we adopted the chemical adsorption properties of sepiolite for deodorization. Initially, sepiolite deodorizing filter cartridges lasted only one year, but nowadays they last seven years, making it far easier to maintain. Finally, in 2016, LIXIL launched the brand new Air Shield Deodorization technology. With this recent innovation, powerful deodorization is now achieved by creating a curtain of air within the toilet bowl and flowing the odoriferous air through the existing deodorizing air filter, shielding the odor from getting out of the toilet bowl.

*Test result by measuring the smell over the toilet bowl, after placing an odor component in the middle of the toilet bowl.

Air Shield Deodorization (2016)

Keeping the odor in the toilet bowl with a curtain of air.

Integrated production line, enabling MADE IN JAPAN shower toilets.

A vast space of 381,635m2, in Chita City, Aichi Prefecture, spacious enough to fit seven Tokyo Domes, is the home to LIXIL's Chita Plant. It is the mother factory of shower toilets, producing all components of shower toilets from resin-molded parts such as toilet seats to electronic boards that control the motion. Shower toilets are also assembled and shipped from this plant. The manufacturing technologies of LIXIL, which we have cultivated over the half century since producing the first shower toilet in Japan, are consolidated into this plant. Chita Plant plays a central role in developing comfortable restroom spaces for people all over the world, while continuing its mission to develop cutting-edge products.

Production system ensuring accurate and speedy delivery.

The production process of each product is complicated, and even the inspection process alone has more than 100 points to be confirmed. In addition, as we manufacture the products as orders come in, various product types are mixed in the production line. The Chita Plant is equipped with robotic technology to accurately identify the various product numbers and shapes through cameras and sensors to produce the products, in addition to the human "eyes" and "hands" carrying out the final assembly. Furthermore, a management system using QR codes as well as a production line that is specifically structured to correctly and swiftly manufacture the required products are enabling the prompt and accurate delivery of ordered products to customers.

To further enhance customer satisfaction.

To produce the Seamless Seat, which eliminated the seam into which stains penetrated, it is necessary to smoothly trim the resin burr caused by compression bonding. While this involves a time-consuming process, we believe it is a well-worthwhile effort, considering the benefit our customers gain in the reduced time and effort required in toilet cleaning. This is why LIXIL continues to manufacture the Seamless Seat, something not offered by our competitors.